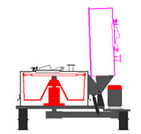

Shell-Pack

| Range | 1 TPH to 12 TPH |

|---|---|

| Pressure | 150 PSI to 300 PSI |

| Type | Straight, Three Pass, Fully Wet Back, Shell & Tube, Smoke Tube, Oil cum Gas Fired Packaged Boiler. |

| Fuel |

|

| Salient | Compatible with most imported Oil/Gas Burners Suitable for Oil as well as Gas Firing |

| Features |

|

Centrifugess

In basket centrifuge, the solids & liquids are separated by centrifugal force using a filter media (usually a cloth) mounted over supporting mesh, which are together supported inside the rotating basket

In basket centrifuge, the solids & liquids are separated by centrifugal force using a filter media (usually a cloth) mounted over supporting mesh, which are together supported inside the rotating basket

The slurry to be filtered is fed through the feed nozzles to the basket and due to centrifugal force the liquid is forced out through the filter media while solids are retained within the filter media inside the basket. These solids then separated are discharged by various discharging methods namely - manually, bag lifting basket, through scrapper operated manually/pneumatically/hydraulically, for which different models are available.

In basket centrifuge, the solids & liquids are separated by centrifugal force using a filter media (usually a cloth) mounted over supporting mesh, which are together supported inside the rotating basket

In basket centrifuge, the solids & liquids are separated by centrifugal force using a filter media (usually a cloth) mounted over supporting mesh, which are together supported inside the rotating basket

The slurry to be filtered is fed through the feed nozzles to the basket and due to centrifugal force the liquid is forced out through the filter media while solids are retained within the filter media inside the basket. These solids then separated are discharged by various discharging methods namely - manually, bag lifting basket, through scrapper operated manually/pneumatically/hydraulically, for which different models are available.

Manual Top Discharge Centrifuge

This is the most versatile & basic model of basket centrifuge for solid & liquid separation.After centrifugation, the solids are unloaded (Scrapped out) manually from top.

This is the most versatile & basic model of basket centrifuge for solid & liquid separation.After centrifugation, the solids are unloaded (Scrapped out) manually from top.

Bag Lift Top Discharge Centrifuge

These types of centrifuge consists of a tapered shell basket for easy removal of filter bag + solids and after centrifuging the solids are unloaded by lifting the basket top along with filter bag and solids. The filter bag is fitted with removal basket top with a bag holding ring. This ring holds the filter bag firmly while filtering & lifting and prevents the bag from tearing and thus preventing solid losses.

The top cover is full mouth opening type and is either manually opened or opened by suitable pneumatically/hydraulically operated cylinders (optional).

These types of centrifuge consists of a tapered shell basket for easy removal of filter bag + solids and after centrifuging the solids are unloaded by lifting the basket top along with filter bag and solids. The filter bag is fitted with removal basket top with a bag holding ring. This ring holds the filter bag firmly while filtering & lifting and prevents the bag from tearing and thus preventing solid losses.

The top cover is full mouth opening type and is either manually opened or opened by suitable pneumatically/hydraulically operated cylinders (optional).

Bottom Discharge Centrifuges

In these types of centrifuges, the centrifuged solids are discharged from the bottom of basket. The discharge outlet from the centrifuge is either fully opening chute type or a single pocket is provided form where the material is discharged.

The scrapping is done by means of a scrapper operated either (a) manually (b) pneumatically or, (c) through hydraulic cylinder.

The DRIVE is furnished by a totally enclosed motor controlled by infinitely variable AC inverter drive to vary basket speed with built in dynamic braking system. The AC drive is incorporated with microcomputer and has a facility to interface with Programmable Logic Controller (PLC) for complete automation.

The centrifuge is driven at 3 speeds i.e. the feed speed, centrifuging speed & scrapping speed (around 80 rpm).

The basket consists of pockets through which solids are discharged from basket.

In these types of centrifuges, the centrifuged solids are discharged from the bottom of basket. The discharge outlet from the centrifuge is either fully opening chute type or a single pocket is provided form where the material is discharged.

The scrapping is done by means of a scrapper operated either (a) manually (b) pneumatically or, (c) through hydraulic cylinder.

The DRIVE is furnished by a totally enclosed motor controlled by infinitely variable AC inverter drive to vary basket speed with built in dynamic braking system. The AC drive is incorporated with microcomputer and has a facility to interface with Programmable Logic Controller (PLC) for complete automation.

The centrifuge is driven at 3 speeds i.e. the feed speed, centrifuging speed & scrapping speed (around 80 rpm).

The basket consists of pockets through which solids are discharged from basket.

Fully Body (Monitor Case) Opening Centrifuge

This is the most versatile & basic model of basket centrifuge for solid & liquid separation. After centrifugation, the solids are unloaded (Scrapped out) manually from top.

This is the most versatile & basic model of basket centrifuge for solid & liquid separation. After centrifugation, the solids are unloaded (Scrapped out) manually from top.